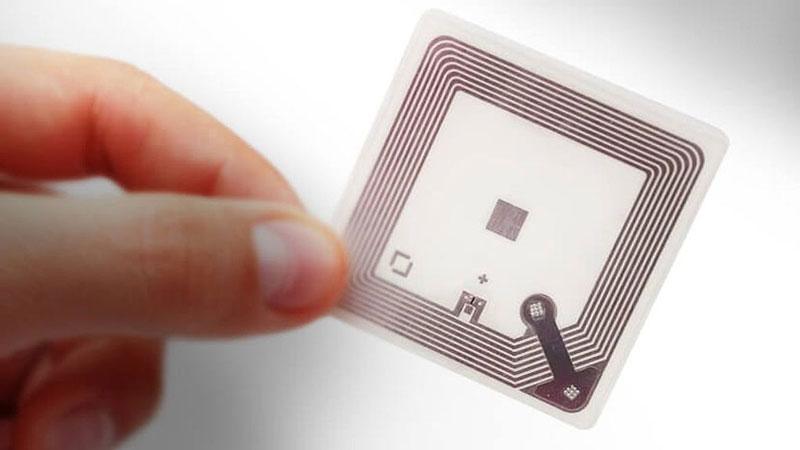

In today's digital era, Radio Frequency Identification (RFID) technology has become an integral part of various industries, enabling efficient tracking and identification of objects. Traditionally, RFID systems rely on tags equipped with integrated circuits (chips) to store and transmit data wirelessly. However, recent advancements in RFID technology have paved the way for a groundbreaking innovation known as Chipless RFID. Unlike its chip-based counterpart, chipless RFID offers a unique approach to identification, eliminating the need for integrated circuits and introducing a new wave of possibilities. In this article, we will explore the concept of chipless RFID, its benefits, applications, and its potential to revolutionize the future of identification.

Chipless RFID, as the name suggests, operates without the presence of a traditional integrated circuit chip. Instead, it utilizes alternative techniques to encode and transmit information wirelessly. These techniques leverage various physical properties and phenomena to achieve identification and data storage. Chipless RFID systems are based on the principle of taggants, which are microscopic elements embedded within objects or materials. These taggants interact with external stimuli, such as electromagnetic waves, to generate a unique response that can be detected and decoded by RFID readers.

The Global Chipless RFID Market Was Estimated To Account For US$ 955.3 Mn In Terms Of Value In 2019.

There are several working principles employed in Chipless RFID systems. Each principle utilizes a different mechanism to encode data and offers unique advantages and applications. Some of the prominent working principles include:

Time-Domain Reflectometry (TDR): TDR-based chipless RFID relies on the measurement of electromagnetic wave propagation time along transmission lines. By embedding conductive elements of varying lengths within an object, different propagation times can be achieved. This time-based information is then decoded to retrieve the encoded data.

Frequency-Domain Reflectometry (FDR): FDR-based Chipless RFID utilizes the analysis of frequency response characteristics of resonant structures. By embedding resonators with unique resonance frequencies in an object, the frequency response spectrum can be measured to extract the encoded data.

Polarization-Based Encoding: This approach relies on the manipulation of polarization states of electromagnetic waves. By employing specially designed materials that alter the polarization of incident waves, chipless RFID tags can encode information based on the changes in polarization.

Chipless RFID technology offers several advantages over traditional chip-based RFID systems, which contribute to its increasing popularity and adoption in various industries. Some key advantages include:

Cost-Effectiveness: Chipless RFID tags are significantly cheaper to produce compared to chip-based tags. The absence of integrated circuits reduces manufacturing costs, making chipless RFID a cost-effective solution for large-scale deployments.

Enhanced Readability: Chipless RFID tags can be read at greater distances and in bulk, allowing for faster and more efficient identification processes. This feature is particularly beneficial in supply chain management, inventory tracking, and logistics operations.

Durability: Chipless RFID tags do not have delicate integrated circuits, making them more resistant to environmental factors such as temperature, moisture, and physical stress. This durability ensures consistent performance even in challenging conditions.

Integration Flexibility: Chipless RFID technology can be easily integrated into existing manufacturing processes and materials. The tags can be printed, sprayed, or embedded, allowing for seamless integration in a wide range of applications.