Introduction:

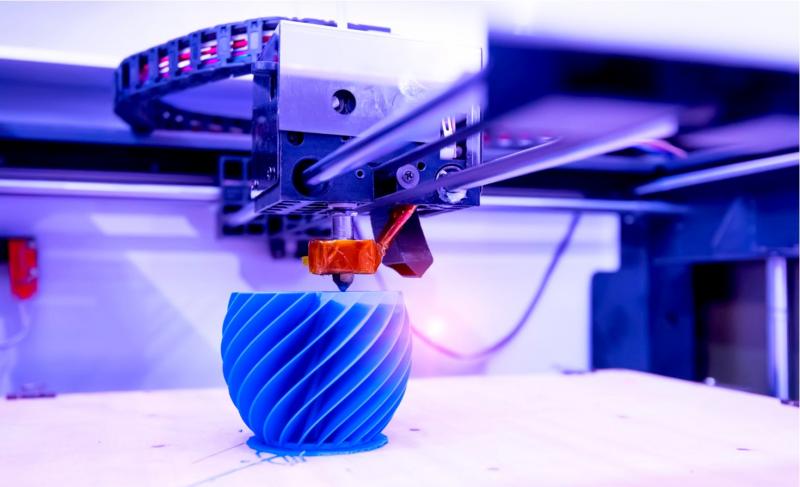

Innovation in 3D printing technology has taken a leap forward with the advent of microscale 3D printing. This cutting-edge technique allows for the creation of intricate, detailed, and precise objects on a miniature scale. From medical advancements to electronics and beyond, microscale 3D printing opens up a world of possibilities for industries and enthusiasts alike.

The Power of Miniaturization:

Microscale 3D printing enables the production of objects at a scale previously unattainable, often down to a fraction of a millimeter. This level of precision is particularly valuable in industries where miniaturization is crucial, such as healthcare, aerospace, and electronics. Medical devices like implants and surgical instruments can be tailored to fit individual patients, enhancing effectiveness and reducing invasiveness. Similarly, electronics can benefit from miniaturization, leading to advancements in wearables, sensors, and microelectromechanical systems (MEMS).

Technologies Driving Microscale 3D Printing:

Several advanced technologies contribute to the success of microscale 3D printing. Two common methods are stereolithography (SLA) and digital light processing (DLP), which use photopolymer resins cured by lasers or projected light, respectively. These techniques achieve remarkable accuracy and surface finish. Another approach is direct laser writing (DLW), utilizing focused laser beams to solidify photosensitive materials layer by layer. Furthermore, two-photon polymerization (2PP) allows for even finer details by using ultrafast laser pulses. Each of these methods offers unique advantages and flexibility, allowing for the creation of intricate microstructures.

The size of the Global Microscale 3D Printing Market was estimated at USD 17.59 billion in 2022 and is projected to reach approximately USD 88.61 billion by 2032, growing at a CAGR of 17.54% from 2023 to 2032.

Applications and Implications:

The applications of microscale 3D printing are vast and ever-expanding. In healthcare, it enables the production of customized medical implants, drug delivery systems, and microfluidic devices for personalized treatments. In electronics, it opens doors to the creation of miniaturized components, such as sensors and antennas, enabling smaller and more efficient devices. Microscale 3D Printing also finds utility in the fields of optics, micro-optics, and microrobotics, providing a platform for advanced research and development.

Microscale 3D printing revolutionizes the way we create and interact with objects on a miniature scale. The precision and versatility offered by this technology have far-reaching implications across industries, leading to breakthroughs in medicine, electronics, optics, and beyond. As this field continues to evolve, we can expect to witness even more astonishing creations emerge from the microscale 3D printers of the future.