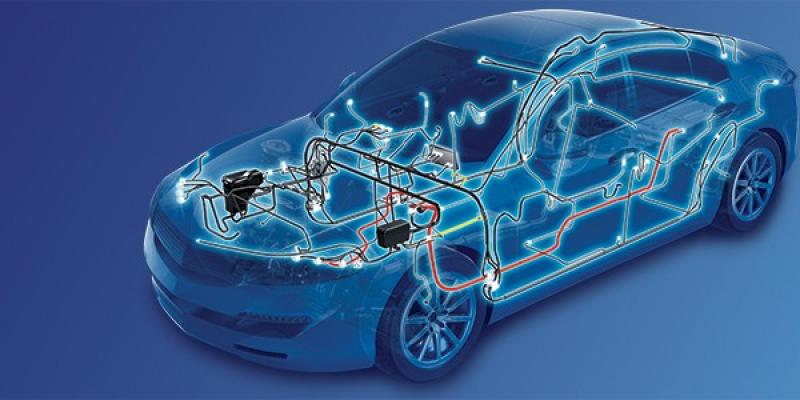

The intricate network of wires in modern vehicles connects various electrical components, enabling seamless communication and functionality. At the heart of this complex system lies the Automotive Wiring Harness. A marvel of engineering, the wiring harness acts as the central nervous system, ensuring the smooth operation of critical systems in automobiles. From power distribution to data transmission, the wiring harness plays a pivotal role in today's automotive industry. In this article, we will explore the significance of automotive wiring harnesses, their components, manufacturing processes, and the future of this indispensable technology.

The Functionality and Importance of Automotive Wiring Harnesses (300 words):

The Automotive Wiring Harness serves as the backbone for electrical systems in vehicles. It comprises a bundle of wires, connectors, terminals, and protective coverings designed to transmit power and signals to various components, such as the engine, transmission, lighting systems, infotainment systems, and more. The wiring harness not only provides reliable electrical connections but also offers protection against environmental factors, such as heat, moisture, vibrations, and abrasion.

The key functions of an automotive wiring harness include:

The Global Automotive Wiring Harness Market Was Valued At US$ 44.83 Bn In 2019 And Is Expected To Reach US$ 62.17 Bn By 2028 At A CAGR Of 4.70% Between 2021 And 2028.

a) Power Distribution: The wiring harness efficiently distributes electrical power from the battery to different electrical components, ensuring reliable operation.

b) Signal Transmission: It facilitates the transmission of signals between various sensors, control units, and actuators, enabling seamless communication and interaction within the vehicle's systems.

c) Safety and Reliability: By organizing and securing the wiring system, the harness minimizes the risk of short circuits, electrical failures, and potential hazards, thereby enhancing the overall safety and reliability of the vehicle.

An Automotive Wiring Harness consists of several essential components meticulously designed to meet the specific requirements of each vehicle. These components include:

a) Wires: The harness incorporates a variety of wires, such as copper or aluminum conductors, insulated with materials like PVC, cross-linked polyethylene, or Teflon. Different colors and gauges are used to distinguish between various circuits.

b) Connectors and Terminals: Connectors serve as the interface between the wiring harness and the vehicle's electrical components. Terminals, which are securely crimped or soldered to the wires, establish the electrical connection within the connectors.

c) Protective Coverings: To safeguard the wires from external factors, protective coverings like convoluted tubing, braided looms, heat shrink tubing, and tape are used. These coverings shield the wires from moisture, chemicals, temperature variations, and physical damage.

d) Fuse Boxes and Relays: These components are integrated into the wiring harness to control the flow of electricity and protect against electrical overloads. Fuse boxes contain fuses that break the circuit in case of an electrical fault, while relays enable the control of high-current devices.

e) Clips and Mounting Brackets: Clips and mounting brackets secure the wiring harness in place, preventing chafing, rattling, or interference with other vehicle components. They also aid in easy installation and maintenance.