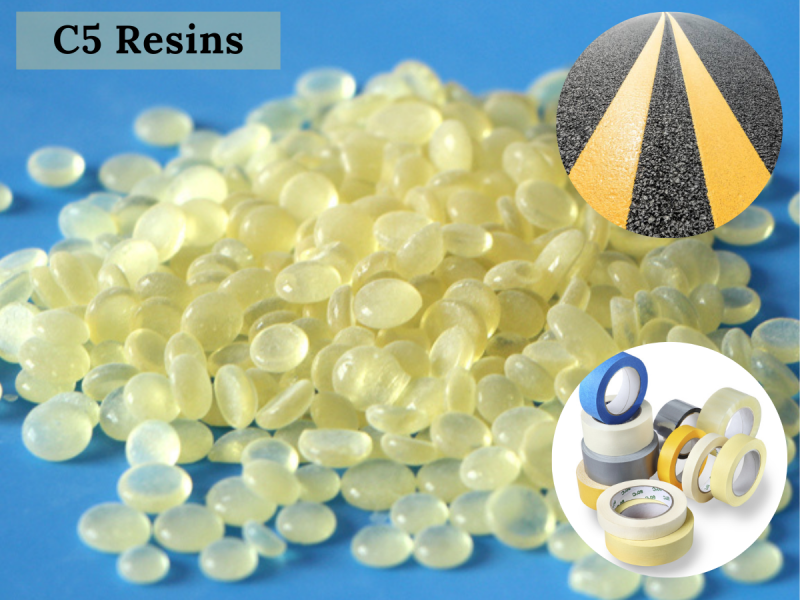

C5 resins are a class of hydrocarbon polymers that have gained significant attention in recent years for their exceptional versatility and utility in the development of advanced adhesives and coatings. Derived from petroleum refining processes, these resins exhibit unique properties that make them an ideal choice for various industrial applications. This article explores the characteristics and applications of C5 resins, highlighting their potential to drive innovation in next-generation adhesives and coatings.

Understanding C5 Resins:

C5 resins are derived from the aromatic hydrocarbon fraction obtained during the cracking of crude oil. These resins primarily consist of aliphatic monomers with five carbon atoms, hence the name "C5." They are known for their excellent balance of properties, combining desirable features from both rosin and C9 resins. This characteristic blend provides C5 resins with exceptional compatibility, adhesion, and thermal stability.

Versatility in Adhesives:

The unique properties of C5 resins make them highly versatile in adhesive formulations. They offer excellent tackiness and adhesion to a wide range of substrates, including metals, plastics, and various composites. Furthermore, C5 resins contribute to enhanced cohesion and flexibility, leading to durable and long-lasting adhesive bonds.

In industries such as packaging, automotive, and construction, C5-based adhesives find extensive use due to their ability to withstand challenging environmental conditions, including high temperatures and moisture exposure. Moreover, the low odor and volatility of C5 resins make them a preferred choice in applications where VOC (volatile organic compounds) emissions need to be minimized.

Advancements in Coatings:

C5 resins have also revolutionized the field of coatings. When incorporated into coating formulations, these resins significantly enhance the performance of the final product. The unique compatibility of C5 resins with various solvents and binders improves the dispersion of pigments, leading to coatings with excellent color stability and vibrant appearance.

Additionally, coatings formulated with C5 resins exhibit superior resistance to weathering, UV radiation, and chemicals. This makes them ideal for protective coatings in outdoor applications, such as architectural coatings, marine paints, and industrial coatings.

Environmental and Sustainability Considerations:

In recent years, there has been a growing emphasis on environmental sustainability and the development of eco-friendly materials. C5 resins offer a positive contribution to this movement due to their reduced VOC emissions and potential for recyclability. As the industry continues to prioritize environmentally friendly solutions, C5 resins emerge as a promising alternative to conventional petroleum-based polymers.

Future Prospects:

With ongoing research and development efforts, the potential applications of C5 resins are likely to expand further. Manufacturers are exploring new ways to modify the properties of C5 resins through chemical modifications, leading to tailored solutions for specific industrial needs. Additionally, advancements in biotechnology may enable the production of C5 resins from renewable sources, further enhancing their sustainability profile.

Conclusion:

C5 resins have emerged as a game-changer in the realm of adhesives and coatings. Their unique blend of properties, coupled with environmental benefits, positions them as a versatile and sustainable option for a wide range of applications. As technology and innovation continue to drive the polymer industry forward, C5 resins are set to play a crucial role in shaping the next generation of adhesives and coatings, meeting the demands of various industries while minimizing environmental impact.