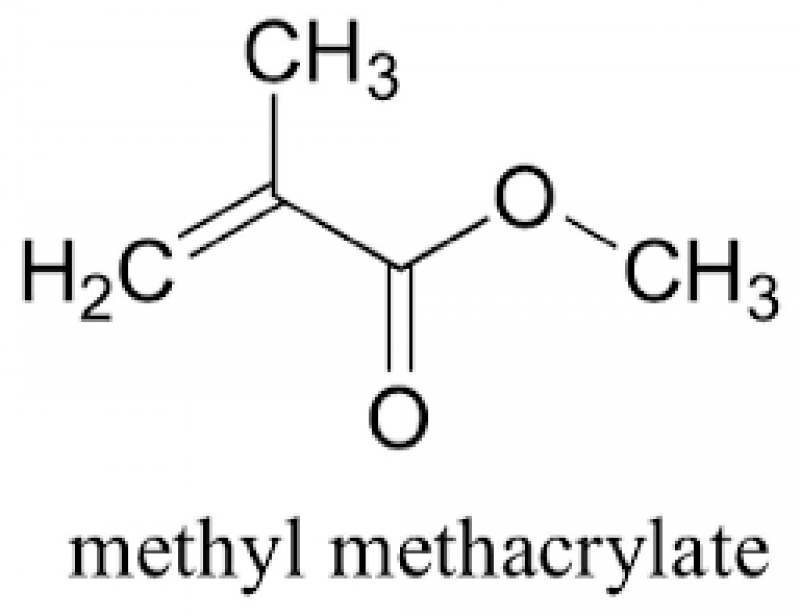

- Methyl methacrylate (MMA) is an organic compound that exists at room temperature as a colorless liquid with an unpleasant odor. It is mainly used as a core ingredient in the production of polymethyl methacrylate (PMMA) which finds wide application in automotive & transportation, building & construction, electronics, signs & displays and other industries owing to its desirable properties such as transparency, lightweight and strength.

The Methyl Methacrylate Market is estimated to be valued at US$ 7,510.7 Mn in 2023 and is expected to exhibit a CAGR of 4.9% over the forecast period from 2023 to 2030, as highlighted in a new report published by Coherent Market Insights

Methyl methacrylate market is driven by rising usage of PMMA in construction industry. PMMA is widely used in glazing and fenestration applications due to its transparency and durability properties. Growing construction activities across developing economies of Asia Pacific and Latin America is promoting increased consumption of PMMA. For example, according to International Trade Administration, the construction industry in China is estimated to grow at over 6% annually through 2025. Further, shifting preferences towards green buildings also supports market growth as PMMA aids in energy conservation. However, volatility in raw material prices remains a key challenge.

Porter's Analysis

Threat of new entrants: Low barrier to entry due to availability of raw materials and technology. However, established players have economies of scale.

Bargaining power of buyers: Buyers have moderate bargaining power due to availability of substitutes. Buyers can negotiate on price offering bulk orders.

Bargaining power of suppliers: Suppliers have moderate bargaining power due to availability of raw materials from different sources. Suppliers can negotiate on price if order quantities are high.

Threat of new substitutes: Threat from substitutes like acrylic acid is low as MMA has irreplaceable properties for end-use applications.

Competitive rivalry: Intense competition among key players to gain market share through product differentiation, cost leadership and expanding applications.

SWOT Analysis

Strengths: Wide applications in diverse end-use industries. Industry leader with integrated production facilities and economies of scale.

Weaknesses: Volatility in raw material prices impact margins. Vulnerable to stringent environmental regulations.

Opportunities: Growing demand from construction and automotive industries in developing countries. New applications development in coatings and adhesives sectors.

Threats: Fluctuations in crude oil prices affecting raw material costs. Shift towards bio-based and recycled polymers limits growth.

Key Takeaways

The global methyl methacrylate market is expected to witness high growth, exhibiting CAGR of 4.9% over the forecast period, due to increasing demand from the construction industry in Asia Pacific. The construction industry is the largest consumer of MMA owing to its usage in making polyester resins and plastics that are used to manufacture various construction materials.

Regional analysis: Asia Pacific dominates the global MMA market and is expected to grow at the fastest pace during the forecast period supported by rising construction activities in China, India. North America and Europe are also significant markets for MMA.

Key players: Key players operating in the methyl methacrylate market are BASF SE, Evonik Industries AG, Arkema Group, The Dow Chemical Company, Akzo Nobel N.V., Sumitomo Chemical Company Limited, Chi Mei Corporation, Huntsman Corporation, Kolon Industries, Karl Jungbecker GmbH & Co. KG, Dhalop Chemicals and Saudi Methacrylate Company.