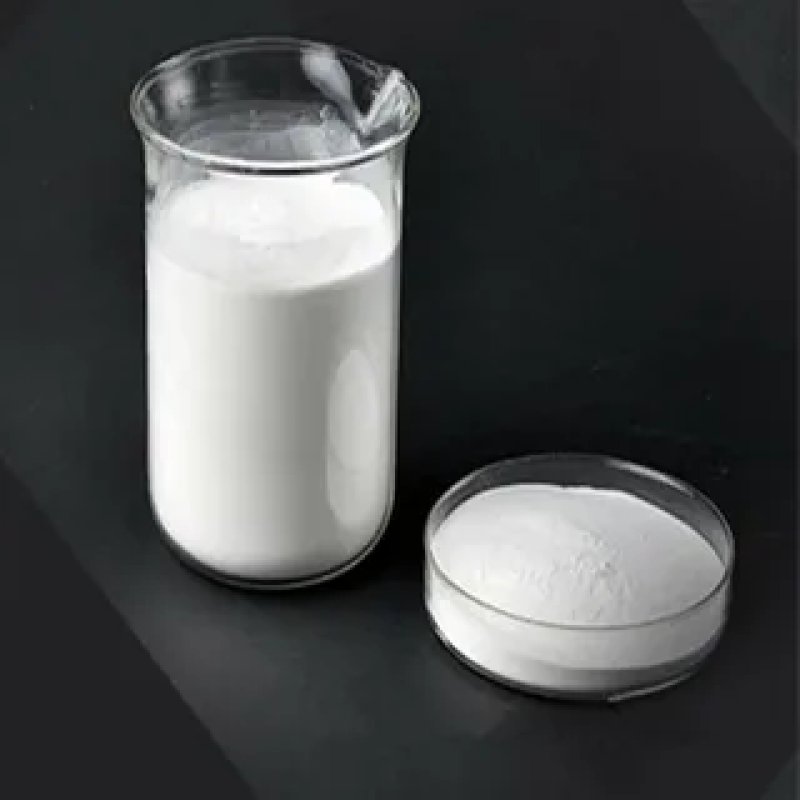

Cellulose derivatives have emerged as pivotal materials across various industries due to their versatile nature and wide-ranging applications. Derived from cellulose, the most abundant natural polymer found in plant cell walls, these compounds undergo chemical modification to enhance specific properties such as solubility, viscosity, and film-forming ability. This has positioned cellulose derivatives as indispensable ingredients in pharmaceuticals, food technology, personal care products, textiles, and construction materials.

Comprehensive Overview of Cellulose Derivative Types and Chemical Properties

Cellulose Derivatives as encompass a variety of chemical compounds, including methyl cellulose, hydroxypropyl methylcellulose (HPMC), carboxymethyl cellulose (CMC), and ethyl cellulose, among others. Each derivative undergoes specific substitution reactions that alter the hydroxyl groups on the cellulose backbone, thereby modifying its physicochemical properties to meet application-specific requirements. For instance, carboxymethyl cellulose is prized for its excellent water solubility and viscosity enhancement, which render it ideal for use in food additives and pharmaceuticals. Hydroxypropyl methylcellulose, by contrast, exhibits unique film-forming and gelation characteristics, making it suitable for controlled drug release and coating applications.

The underlying chemical properties of cellulose derivatives influence their application scope in significant ways, affecting viscosity, emulsifying capacity, and thermal stability. These properties ensure that cellulose derivatives function effectively as thickeners, stabilizers, binders, and emulsifiers across different sectors, particularly in formulations requiring biocompatibility and biodegradability.

Cellular Derivative Applications Driving Industry Growth Globally in 2025

The demand for cellulose derivatives is propelled by their broad spectrum of applications. In the pharmaceutical industry, cellulose derivatives serve as excipients, playing crucial roles in tablet binding, controlled drug delivery, and capsule coating. Their non-toxic nature and safety profiles comply with stringent pharmaceutical standards, which amplifies their preference in drug formulation.

The food and beverage sector extensively utilizes cellulose derivatives as thickeners, stabilizers, and fat replacers to enhance texture and extend shelf life. Additionally, personal care products such as shampoos, lotions, and toothpaste incorporate cellulose derivatives to improve consistency and moisturization.

Construction materials also benefit from cellulose derivatives, particularly in cement and mortar formulations, where they act as water retention agents and improve workability. The growing demand for sustainable and eco-friendly building materials further accelerates their usage in this segment. Meanwhile, the textile industry leverages cellulose derivatives for fabric finishing and sizing, ensuring improved fabric strength and texture.

Navigating Cellulose Derivative Market Analysis and Key Insights for Strategic Decisions

Industry players and investors seeking detailed analytical insights can access in-depth market research reports available online, which shed light on regional demand patterns, competitive landscapes, and emerging growth opportunities within the cellulose derivatives sector. These comprehensive reports also explore factors such as raw material availability, supply chain dynamics, and regulatory frameworks influencing market trends.

A clear understanding of the cellulose derivatives supply chain—from wood pulp extraction and chemical processing to final product distribution—assists businesses in optimizing procurement and manufacturing strategies. Market research reports often feature competitive benchmarking that identifies leading manufacturers and technological innovations shaping the competitive environment.

Furthermore, analysis of geographic segmentation reveals growing consumption hubs in Asia-Pacific, North America, and Europe, guided by rising industrialization and consumer preferences for natural and sustainable products. Reports provide stakeholders with forecasts and scenario analysis crucial for making informed investment and operational decisions.

Key Commercial Drivers and Economic Impact of Cellulose Derivative Products Today

The cellulose derivative market benefits commercially from increasing regulatory support for biodegradable and renewable materials, contributing to sustainable development goals worldwide. Corporate commitments to environmentally friendly production methods have elevated demand for cellulose-based products over synthetic alternatives, enhancing commercial potential.

Rising consumer awareness about health and safety aspects primarily in pharmaceutical and food sectors also drives growth. The shift toward clean-label food ingredients and natural cosmetic formulations fuels this trend. Moreover, innovations in product formulations and advances in cellulose derivative chemistry boost efficiency and performance, widening market acceptance.

On the economic front, cellulose derivatives contribute significantly to the bio-based materials industry, promoting value addition in agriculture and forestry sectors. They support job creation in chemical processing, research and development, and product manufacturing, thereby fostering regional economic growth.

Transactional Insights into Cellulose Derivative Procurement and Supply Chain Efficiencies

For buyers and procurement professionals, navigating cellulose derivative sourcing involves evaluating factors such as quality consistency, pricing stability, and supplier reliability. Transactional insights derived from market intelligence enable companies to negotiate favorable contracts and optimize supply chain logistics.

Bulk purchasing trends reflect economies of scale, especially for large end-users in pharmaceuticals and construction. Transparent market pricing data assists in budgeting and forecasting procurement expenses. Moreover, technological advancements in manufacturing contribute to competitive pricing, benefiting buyers.

Supply chain efficiencies, including inventory management, transportation, and raw material sourcing, remain critical to maintaining uninterrupted production cycles. Market monitoring tools and strategic partnerships with suppliers decrease risk exposure to market fluctuations and regulatory changes.

Get This Report in Japanese Language: セルロース誘導体

Get This Report in Korean Language: 셀룰로오스 유도체

Read More Articles Related to this Industry- Acetic Acid Derivatives: Key Compounds and Their Growing Demand

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)