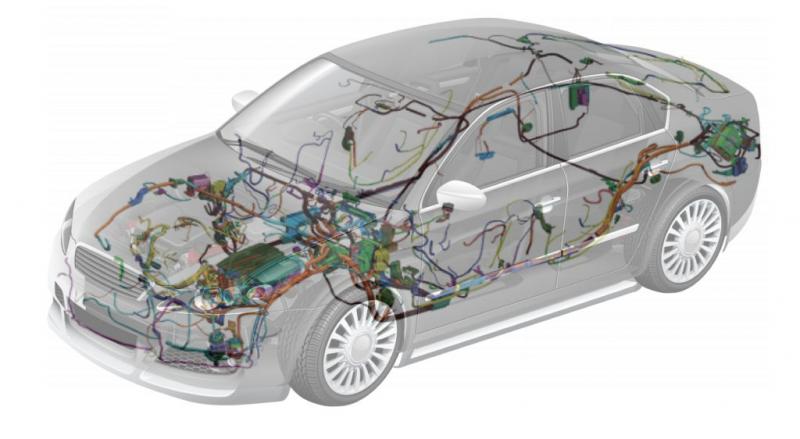

As automotive technology continues to evolve, wiring harnesses have undergone significant advancements to meet the increasing demands of modern vehicles. Some notable advancements include: Modularity and Customization: Wiring harnesses are now designed with modular components that allow for easy customization and adaptation to different vehicle models and configurations. This modular approach simplifies production, assembly, and maintenance processes. An assembly of wires, terminals, and connectors known as a "Automotive Wiring Harness" runs throughout the vehicle to transport data and electrical power.

The primary function of an Automotive Wiring Harness is to provide a systematic and organized approach to electrical wiring in vehicles. Some key functions and benefits include: Efficient Power Distribution: Wiring harnesses distribute electrical power from the battery and alternator to different components, ensuring efficient and reliable operation.

Reduced Installation Time: By using a pre-assembled wiring harness, the installation process becomes faster and more efficient. The harness eliminates the need for individual wire routing, connection crimping, and insulation, saving significant time during vehicle assembly.

Automotive wire harness is integrated to connect various vehicle parts, including the body, engine, dashboard, chassis, and others. It is developed to meet the electrical and dimensional requirements of automobiles. To ensure fundamental operation and improved safety, an Automotive Wiring Harness facilitates transfer of control signals and electrical power to electronic and electrical devices. High-Speed Data Transmission: With the integration of advanced electronic systems and connectivity features in vehicles, wiring harnesses are capable of supporting high-speed data transmission.