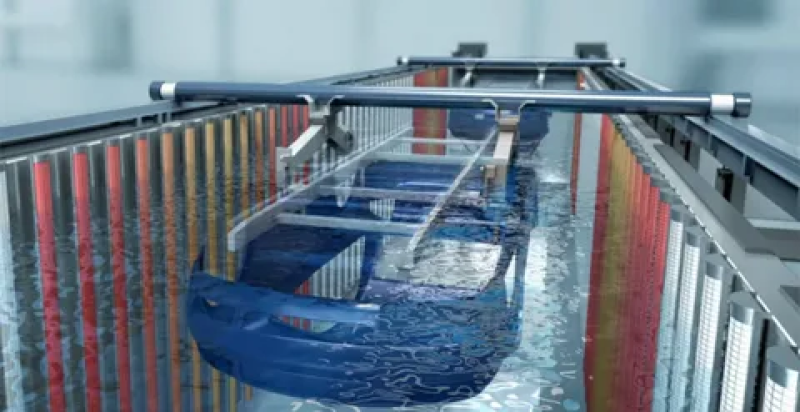

Electrodeposition coating, commonly known as E-Coat, has emerged as a vital surface finishing technique applied extensively in various industries, from automotive manufacturing to consumer electronics. This process involves the submersion of a metal workpiece into a water-based solution containing electrically charged paint particles, which are deposited evenly onto the substrate when an electric current is passed through the solution. The result is a highly uniform, durable coating that offers superior corrosion resistance, excellent paint adhesion, and environmental benefits compared to traditional coating methods.

E-Coat technology revolutionizes the finishing process by creating an even and thin film on complex-shaped components, developing a protective barrier that extends the lifecycle of metal parts significantly. This coating method ensures superior coverage in hard-to-reach areas, reducing the need for additional layers of finishing. Due to its waterborne nature, E-Coat minimizes volatile organic compound (VOC) emissions, making it an environmentally sustainable option for companies aiming to meet stricter regulatory standards. The rise in demand for lightweight and corrosion-resistant materials in sectors such as automotive, aerospace, and appliances underscores the increasing adoption of E-Coat technology globally.

Understanding Different Types of E-Coating Processes Used in Industries

E-Coat is divided primarily into two categories based on the charge of paint particles: cathodic and anodic electrodeposition. Cathodic electrodeposition (commonly referred to as cationic E-Coat) is the more widespread method, favored for its excellent corrosion protection and adhesion properties. In this process, the metal component acts as the cathode, attracting positively charged paint particles. Conversely, anodic electrodeposition places the metal workpiece as the anode, attracting negatively charged particles. Though less common, anodic E-Coat is utilized in specific applications requiring distinct surface characteristics.

Each E-Coat process is optimized for various substrates and industrial requirements. Manufacturers must choose the appropriate type based on factors such as the nature of corrosion protection needed, paint resistance, and compatibility with subsequent finishing layers. The precise control of parameters like voltage, time, and temperature during electrodeposition ensures high-quality coatings, with thickness often ranging between 15 to 30 microns per application. Post-coating, the parts typically undergo curing in ovens at controlled temperatures, which solidifies the coating and enhances durability.

E-Coat Market Dynamics and Industry Trends Driving Growth

The ongoing advancements in materials engineering, combined with growing environmental regulations, have propelled the e-coat market into a phase of significant expansion. Increasing production in end-user sectors such as automotive assembly lines and electrical equipment manufacturing has created robust demand for cost-effective, sustainable surface finishing technologies. Industries are gravitating towards E-Coat because it delivers both performance and efficiency—resulting in reduced waste and energy usage during manufacturing processes.

Another notable driver is the push toward electric vehicle production, which emphasizes lightweight and corrosion-resistant components to maximize battery longevity and vehicle performance. The e-coat process’s ability to deliver precise, uniform coatings on lightweight metals such as aluminum alloys aligns with these evolving industry requirements. Additionally, the surge in infrastructure projects and consumer goods manufacturing continues to boost the deployment of electrodeposition coatings worldwide.

E-Coat Technical Specifications and Its Competitive Advantages over Alternatives

An important benefit of E-Coat technology lies in its tightly controlled coating thickness, which minimizes material consumption without compromising protection. Unlike spray painting or dip coating, electrodeposition ensures that paint particles migrate uniformly to all surfaces, including interior cavities and sharp edges. This uniformity prevents typical paint defects such as sagging, uneven coverage, or thickness variation common in manual applications.

The chemical composition of e-coat paints includes epoxy resins or acrylics, with specific formulations designed to maximize flexibility, thermal resistance, and UV stability based on the target application. The low curing temperatures used in E-Coat processes help in preserving substrate integrity, which is especially critical for sensitive metal alloys and complex assemblies. Furthermore, the process is adaptable to automation, reducing labor costs and increasing throughput — substantial commercial advantages for large-scale manufacturers.

Additionally, E-Coat meets stringent environmental compliance guidelines, offering a low-emission finishing process favored by regulatory bodies worldwide. This eco-friendly profile enhances corporate sustainability goals, attracts environmentally conscious consumers, and strengthens brand reputation in competitive markets.

Navigating In-Depth E-Coat Industry Analysis and Market Forecast Resources

For professionals and investors seeking deeper insights into E-Coat market dynamics, detailed industry reports provide comprehensive data on regional market trends, growth potential, competitive landscape, and technological advancements. Such analytics facilitate strategic market entry decisions, informed procurement, and capital allocation within the coating industry ecosystem.

These resources typically include granular information on key market segments, including automotive, industrial equipment, and consumer electronics coatings, with forecasts of demand fluctuations based on evolving industrial applications. By exploring these analytical tools, stakeholders can gain foresight into supply chain challenges, raw material pricing trends, and emerging regulatory impacts that influence the E-Coat market.

The availability of up-to-date market analysis supports decision-makers in crafting effective business strategies, enabling companies to leverage the competitive advantages of electrodeposition coating technology in expanding global markets.

Get This Report in Japanese Language: Eコート

Get This Report in Korean Language: 전자 코팅

Read More Articles Related to this Industry- Key Development in Gas Chromatography

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)