Material Selection and Certification

The materials used in aircraft parts undergo stringent selection processes to ensure maximum safety. Vital components are made from high-grade alloys that can withstand tremendous stresses. Titanium, aluminum and specialty steels are commonly used based on the required properties.

Before production, Aircraft Parts must clear certification standards set by regulatory authorities. Tests evaluate factors such as corrosion resistance, tensile strength and operating temperature tolerances. Only supplies from approved sources are utilized to maintain full traceability. Strict protocols are followed to avoid defects from material handling and storage.

Manufacturing Processes

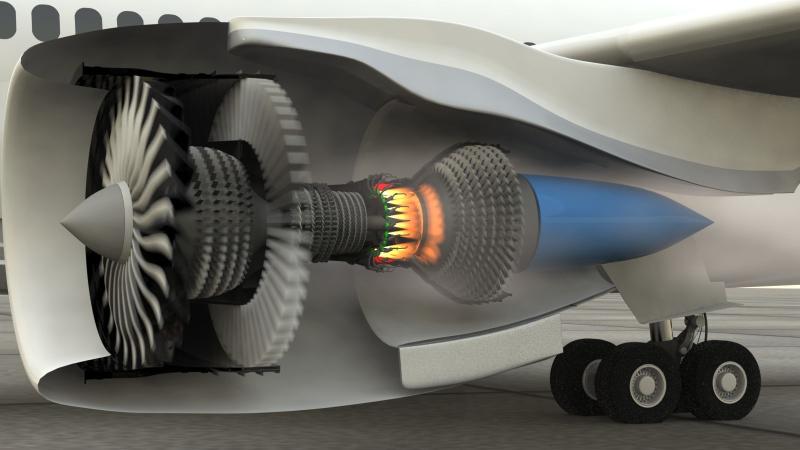

Aircraft components involve complex manufacturing methods with tight tolerances. Machining removes material using tools likelathes, mills and grinding machines. Near-net shapes are often achieved in a single setup to maximize efficiency and minimize waste. Non-traditional techniques like additive manufacturing also see increasing applications for complex geometries.

Assembly processes bring together made-to-precision parts through steps such as riveting, bolting and bonding. Jigs and fixtures precisely locate pieces for repeatable results. Surface finishing operations such as plating further enhance attributes. Quality assurance checks validate dimensions and functional testing at each stage before approval. Automated systems paired with experienced craftsmanship deliver consistency.

Supplier Qualification and Quality Management

Original equipment manufacturers qualify partners through a meticulous vetting process. This evaluates production capabilities, engineering expertise, inventory management and quality certifications. Only sources meeting the stringent AS/EN/JISQ standards are approved as authorized dealers.

Process audits and material surveillance programs help suppliers sustain compliance. Statistical process controls detect aberrations. Supplier parts are also screened using non-destructive testing techniques like eddy current and ultrasonic inspection. Corrective actions address any non-conformances to ensure zero defects. Careful traceability allows efficient lot isolation in case of field issues.

Maintenance, Repair and Overhaul

As aircraft age, their parts progressively wear out through operational stresses. Maintenance activities replace such deteriorated components to restore performance and extend life. Technicians disassemble systems and evaluate parts against engineering limits using precision gauging.

Repair involves rectifying imperfections to restore parts to like-new condition. Methods include restoring corrosion protection, smoothening rough surfaces and building up worn sections through welding or composite patches. Overhaul completely remanufactures a part by replacing all unusable sub-assemblies and material.

Rigorous process validations guarantee repaired/overhauleditems match original specifications. Life limits factor in maintenance histories to determine residual useful life. Recertification testing clears components for return to active service. Such sustainment practices make efficient use of existing resources while maintaining safety.

Part Substitution Considerations

Substitution entails replacing a part with an alternative outside standard configurations. While offering cost savings, it requires careful review. Alternate items must replicate mandated interfaces, functionalities and certification compliance.

Minor changes may comply through "as good as" equivalence demonstrations. More substantial deviations mandatetesting and supplementary type certification. It is standard practice to obtain approvals from regulatory bodies as well as aircraft/engine OEMs for substitution concurrences. Proper documentation allows traceability throughout service lives.

Aftermarket aircraft parts

A robust aftermarket distribution chain serves aircraft across their missions worldwide. Distribution centers stock extensive part inventories for swift fulfillment of orders. Digital supply chain systems monitor real-time availability.

Third party logistics providers expertly package, transport and deliver goods. Field service representatives install parts, return unserviceable items and support maintenance activities.

In Summary, comprehensive services and competitive pricing sustain fleet operations cost-effectively. Independent specialized hangars even perform complex maintenance, repair and modernization programs. Together with OEM assistance, such infrastructure ensures continued airworthiness throughout decades of frontline operation.

For Deeper Insights, Find the Report in the Language that You want:

About Author:

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )