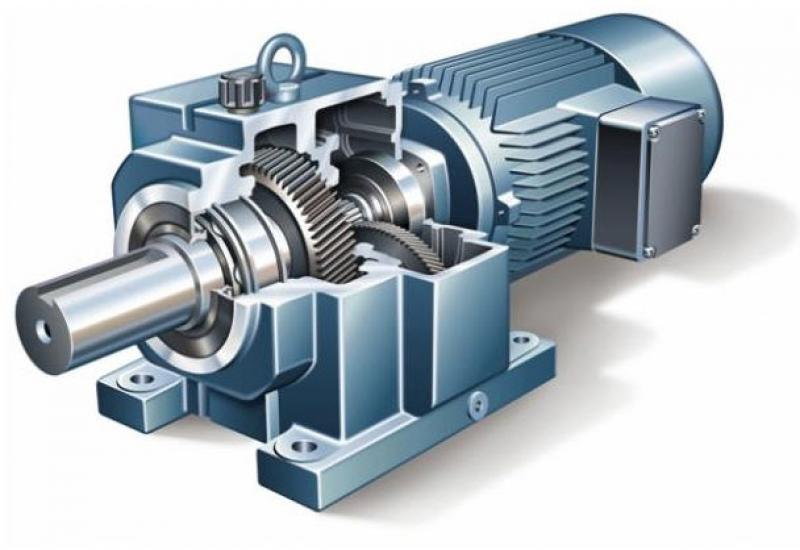

In the world of mechanical engineering, precision gear boxes stand as a testament to the pursuit of perfection in motion control. These advanced gear systems play a crucial role in a wide range of applications, from industrial machinery to robotics and automotive systems. Precision gearboxes are engineered to deliver exceptional accuracy, efficiency, and reliability, making them an indispensable component in the smooth operation of various mechanical systems.

One of the key features of precision gearboxes is their ability to provide high gear ratios with minimal backlash. Backlash refers to the amount of play or clearance between gear teeth, which can introduce inaccuracies and reduce the precision of motion control. Precision gearboxes are meticulously designed and manufactured to minimize backlash, ensuring that rotational motion is transmitted with utmost accuracy and consistency. This precision is essential in applications where precise positioning and motion control are critical, such as CNC machines, robotic arms, and optical equipment.

Additionally, precision gearboxes are engineered to optimize power transmission and efficiency. With their superior gear design and high-quality materials, these gearboxes minimize friction and energy losses during power transmission. This efficiency not only reduces energy consumption but also translates into higher performance and productivity in various industrial processes. Moreover, the durability and reliability of precision gearboxes make them ideal for applications that require continuous and high-speed operations. Whether in automotive transmissions, aerospace systems, or medical devices, precision gearboxes contribute to the seamless and reliable functioning of complex mechanical systems.

Furthermore, advancements in technology have led to the integration of precision gearboxes with other cutting-edge innovations. For instance, some precision gearboxes are now equipped with sensors and monitoring systems, allowing for real-time performance analysis and predictive maintenance. This smart gearbox technology helps in preventing unexpected failures, minimizing downtime, and optimizing equipment life. Moreover, advancements in materials and manufacturing techniques have resulted in lightweight and compact precision gearboxes, enabling their use in space-constrained applications without compromising performance.