The Science of Conformal Coatings: Advancements in Materials and Applications for Electronics Protection

Conformal coatings play a vital role in safeguarding sensitive electronic components from a range of environmental hazards. These coatings are thin, protective layers applied to electronic assemblies and circuit boards to prevent damage from moisture, dust, chemicals, and other contaminants. By providing a barrier against external elements, conformal coatings significantly enhance the reliability and longevity of electronic devices, making them essential in various industries, including automotive, aerospace, consumer electronics, and medical devices.

The Need for Conformal Coatings

Electronic devices are becoming increasingly ubiquitous in modern life, and their functionality often relies on delicate circuitry that can be susceptible to external influences. Moisture, dust, and corrosive substances can cause short circuits, reduce performance, and ultimately lead to the failure of electronic components. Additionally, extreme temperatures and mechanical stress can also impact device performance. Conformal coatings act as a protective shield, mitigating these risks and ensuring electronic devices perform optimally, even in harsh environments.

Types of Conformal Coatings

Several types of conformal coatings are available, each with specific properties tailored to different applications. Some common types include:

Acrylic Coatings: Known for their ease of application and removal, acrylic coatings offer good protection against moisture and dust. They are cost-effective and well-suited for consumer electronics.

Silicone Coatings: These coatings have excellent thermal resistance and flexibility, making them ideal for devices subjected to extreme temperature variations. Their high dielectric strength also makes them suitable for high-voltage applications.

Polyurethane Coatings: With a higher chemical resistance compared to acrylics, polyurethane coatings are often used in industrial settings where exposure to solvents and chemicals is a concern.

Parylene Coatings: Parylene is a unique, ultra-thin and pinhole-free coating that provides outstanding protection against moisture, chemicals, and extreme temperatures. Its ability to penetrate small gaps and cover complex geometries makes it popular in medical and aerospace applications.

Application Techniques

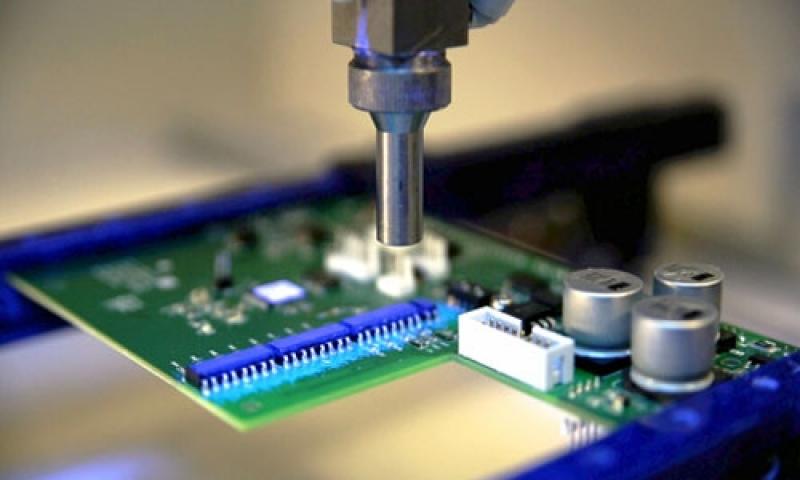

Conformal coatings can be applied using various techniques, including brushing, spraying, dipping, and selective coating. Each method has its advantages, and the choice depends on factors such as production volume, complexity of the assembly, and desired coating thickness. Regardless of the technique used, it is crucial to ensure uniform coverage and proper curing for optimal protection.

Conclusion

Conformal coatings have become indispensable for enhancing the reliability and performance of electronic devices. With advancements in coating materials and application techniques, they continue to evolve to meet the ever-changing demands of the electronics industry. From consumer electronics to critical medical devices and aerospace components, conformal coatings play a vital role in extending the lifespan of electronic products and ensuring their functionality in the most challenging environments. As technology continues to progress, so too will the capabilities of conformal coatings, keeping our electronic devices safe, reliable, and cutting-edge.