In recent years, the concept of the Digital Twin has emerged as a revolutionary paradigm in the world of technology and innovation. With its ability to bridge the physical and digital realms, the digital twin has proven to be a game-changer in various industries, from manufacturing and healthcare to urban planning and beyond. This unique and powerful concept holds tremendous potential for transforming how we design, operate, and optimize systems, offering new opportunities for efficiency, productivity, and innovation.

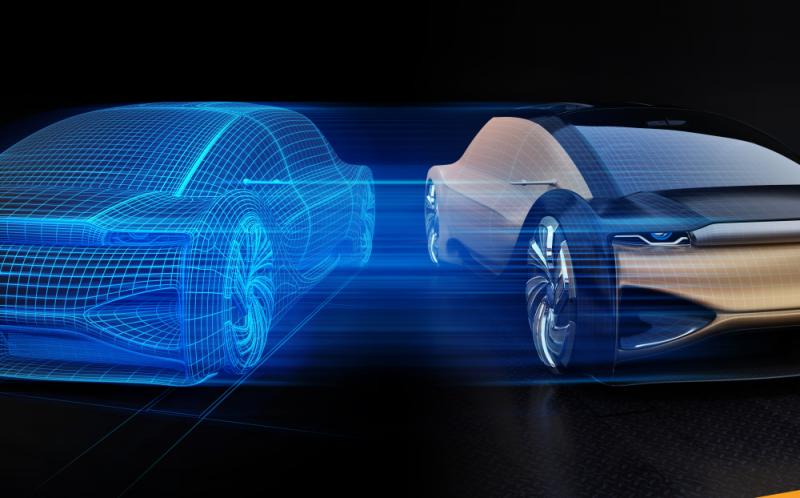

At its core, a Digital Twin is a virtual representation of a physical object, system, or process. It goes far beyond a simple 3D model or simulation. It captures and combines real-time data, analytics, and contextual information to create a dynamic and interactive mirror image of the physical counterpart. The digital twin provides a holistic view of the object or system, allowing for deep insights, analysis, and prediction of its behavior, performance, and maintenance needs

The creation of a Digital Twin involves multiple components. First, there is the physical object itself, equipped with various sensors and data collection mechanisms. These sensors continuously monitor and capture data about the object's operating conditions, performance metrics, environmental factors, and other relevant parameters. This data is then transmitted to the digital twin, where it is processed, analyzed, and visualized in a meaningful and actionable manner.

The Digital Twin serves as a virtual laboratory, enabling engineers, designers, and operators to experiment, simulate, and test various scenarios without the need for physical intervention. By manipulating the digital twin, stakeholders can gain insights into the behavior and performance of the physical object under different conditions, optimizing its design, performance, and maintenance strategies.

One of the key advantages of the digital twin lies in its ability to enable predictive maintenance. By continuously monitoring and analyzing real-time data from the physical object, the digital twin can detect patterns, anomalies, and potential issues before they escalate into costly failures. This proactive approach to maintenance minimizes downtime, reduces repair costs, and extends the lifespan of assets, thus improving overall operational efficiency.

Moreover, the Digital Twin facilitates the optimization of processes and operations. By leveraging real-time data and advanced analytics, organizations can identify bottlenecks, inefficiencies, and optimization opportunities within their systems. Whether it's optimizing the flow of goods in a manufacturing plant or fine-tuning energy consumption in a smart city, the digital twin provides a platform for data-driven decision-making and continuous improvement.

The concept of the Digital Twin has found its applications in various domains. In manufacturing, digital twins enable the creation of intelligent factories where production lines are monitored, simulated, and optimized in real-time. By connecting the physical and digital realms, manufacturers can achieve higher levels of productivity, quality control, and flexibility.

In healthcare, digital twins have the potential to revolutionize personalized medicine. By creating virtual replicas of patients, doctors can simulate the effects of different treatments and interventions, leading to more targeted and effective healthcare solutions. Digital twins also play a crucial role in medical device development, enabling rigorous testing and validation before physical prototypes are manufactured.