Introduction

In the realm of precision electronics manufacturing, conformal coatings play a crucial role in enhancing performance, durability, and protection against harsh environments. However, there are instances when these coatings need to be removed or stripped for rework, repair, or component replacement. This necessity has given rise to the conformal coating stripper market, providing specialized solutions for safely and efficiently removing conformal coatings. This article delves into the dynamics, trends, challenges, and potential of the conformal coating stripper market.

Market Dynamics

The conformal coating stripper market has gained significance in industries such as electronics, aerospace, automotive, and medical devices, where the delicate balance between protective coatings and the need for rework is vital. Conformal coating strippers facilitate the removal of coatings while safeguarding the integrity of underlying components.

Key Factors Driving the Market

-

Rework and Repair Needs: In precision electronics manufacturing, rework and repair are common requirements. Conformal coating strippers enable technicians to precisely remove coatings without causing damage to sensitive components.

-

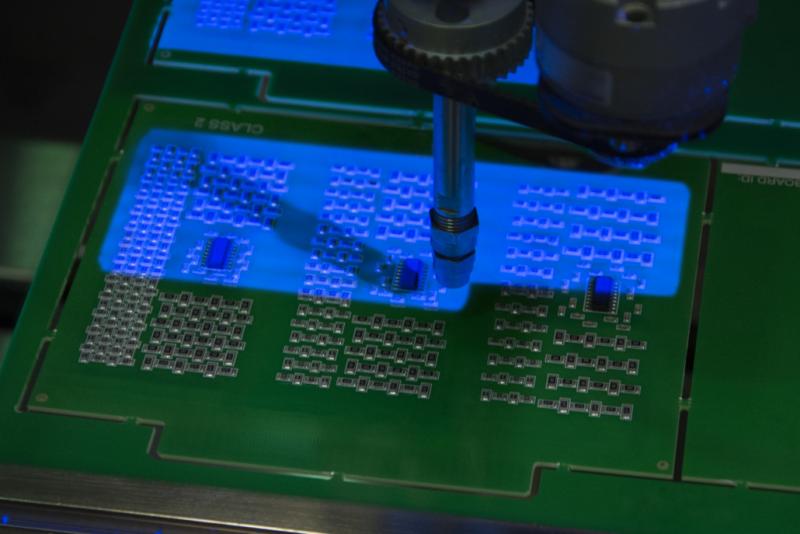

Increasing Miniaturization: As electronics continue to shrink in size, the demand for precision coating removal has surged. Conformal coating strippers offer a solution to maintain accuracy and functionality in smaller spaces.

-

Environmental Regulations: Stringent environmental regulations have prompted the development of conformal coating strippers that are eco-friendly and compliant with safety standards.

-

Growing Electronics Industry: The expanding electronics industry, including the proliferation of consumer electronics and advancements in communication technologies, drives the need for effective coating removal solutions.

Market Segmentation

The conformal coating stripper market can be segmented based on the type of stripper, substrate, and end-users.

By Type of Stripper

- Solvent-Based Strippers

- Alkaline-Based Strippers

- Thermal Strippers

- Mechanical Strippers

By Substrate

- Printed Circuit Boards (PCBs)

- Semiconductor Devices

- Electronic Assemblies

By End-Users

- Electronics Manufacturing

- Aerospace and Defense

- Automotive

- Medical Devices

- Others

Trends and Opportunities

-

Environmentally Friendly Solutions: The market is witnessing a shift towards environmentally friendly and sustainable conformal coating strippers, driven by consumer demand and regulatory pressures.

-

Advanced Formulations: Ongoing research is focused on developing conformal coating strippers that are compatible with a wide range of coatings, substrates, and component materials.

-

Precision Application: Manufacturers are exploring the development of conformal coating strippers that can be precisely applied, ensuring minimal contact with unaffected areas.

-

Automation and Robotics: The integration of automation and robotics in conformal coating stripping processes enhances accuracy, efficiency, and repeatability.

Challenges and Outlook

While the conformal coating stripper market holds potential, it also faces certain challenges:

-

Compatibility and Selectivity: Strippers need to be compatible with various coatings and substrates while being selective in targeting the desired layer.

-

Residue Management: Efficient residue management post-stripping is crucial to prevent any adverse effects on subsequent processes or performance.

-

Technological Complexity: Developing effective and safe conformal coating stripping solutions requires extensive research and technological expertise.

-

Adoption and Awareness: Educating manufacturers about the benefits and proper use of conformal coating strippers is essential for market expansion.

Conclusion

In the intricate world of precision electronics, the conformal coating stripper market serves as a vital bridge between protective coatings and the need for rework and repair. As technology continues to advance and electronics become more pervasive, the demand for accurate and efficient conformal coating removal solutions is poised to grow. Innovations in environmentally friendly formulations, precision application techniques, and automation will shape the future of the conformal coating stripper market, ensuring the longevity, reliability, and functionality of precision electronic devices across various industries.