Aluminum Extrusion Market: Pioneering Versatility and Sustainability in Modern Industries

Introduction

The aluminum extrusion market has emerged as a pivotal segment within the global metals and manufacturing industries, offering a wide range of applications across various sectors. Aluminum extrusion is a versatile and cost-effective process that shapes aluminum alloys into complex profiles, catering to diverse design requirements. This article delves into the dynamics of the aluminum extrusion market, exploring its growth drivers, sustainable initiatives, and innovations shaping modern industries.

Advantages of Aluminum Extrusion

Aluminum extrusion offers a myriad of advantages that make it an ideal choice for engineers, architects, and manufacturers alike. The process allows for the creation of intricate and custom-designed profiles, providing exceptional design flexibility for applications in construction, transportation, electronics, and more.

The lightweight nature of aluminum makes it an attractive alternative to other metals, reducing overall product weight and transportation costs. Moreover, aluminum's excellent corrosion resistance and durability ensure longevity and low maintenance costs, making it particularly suitable for outdoor and industrial applications.

Sustainability and Circular Economy

In recent years, the aluminum extrusion market has embraced sustainability as a core principle. Aluminum is a highly recyclable material, and the recycling process consumes only a fraction of the energy needed for primary aluminum production. This focus on recycling aligns with the principles of a circular economy, minimizing waste and conserving resources.

Manufacturers are increasingly utilizing secondary or post-consumer aluminum to produce extruded profiles, reducing the industry's carbon footprint. Additionally, advancements in technology and process optimization have led to reduced energy consumption during extrusion, further enhancing the industry's sustainability credentials.

Innovations in Aluminum Extrusion

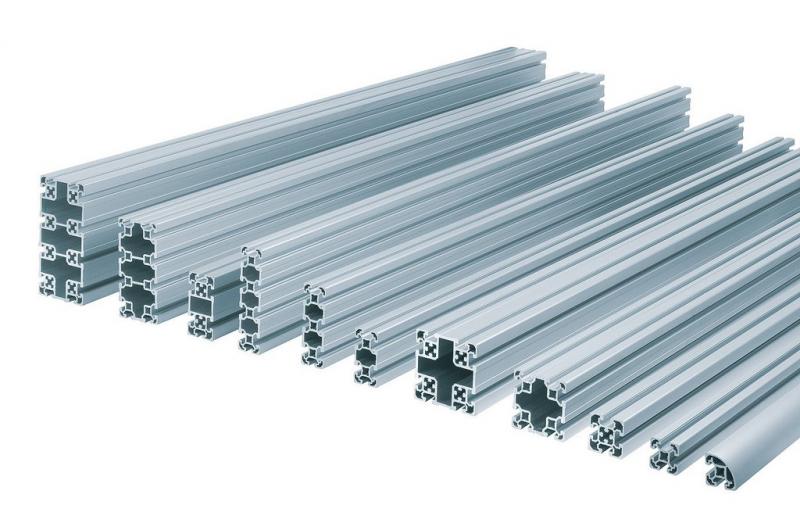

The aluminum extrusion market has witnessed continuous innovation, enabling the production of profiles with higher complexity and precision. Advanced extrusion techniques, such as multi-void hollow profiles and thin-walled sections, cater to the growing demand for lightweight and intricate designs.

Furthermore, advancements in alloy composition have expanded the range of aluminum extrusions available. High-strength alloys, corrosion-resistant alloys, and specialized heat-treatable alloys enhance the performance of extruded profiles in specific applications, from automotive components to architectural facades.

Market Growth and End-Use Applications

The aluminum extrusion market is witnessing robust growth worldwide, driven by its widespread applications across diverse industries. In the construction sector, aluminum extrusions find use in window frames, curtain walls, and roofing systems, thanks to their strength, thermal performance, and design versatility.

In the automotive industry, extruded aluminum profiles contribute to lightweighting efforts, improving fuel efficiency and reducing emissions. Additionally, extruded components are utilized in electronics, transportation, and consumer goods, underlining their universal applicability.

Global Demand and Regional Trends

Developed regions, such as North America and Europe, continue to be major consumers of aluminum extrusions, owing to the presence of established industries and significant investments in infrastructure and construction. The Asia Pacific region, with its rapid industrialization and urbanization, is witnessing substantial growth in the demand for aluminum extrusions.

Conclusion

The aluminum extrusion market stands at the forefront of modern industries, driving innovation, sustainability, and efficiency. As manufacturers and industries increasingly prioritize lightweight and eco-friendly materials, aluminum extrusions have emerged as a leading solution, catering to a wide range of applications.

The industry's commitment to sustainability, coupled with continuous advancements in technology and alloy compositions, promises to shape the future of the aluminum extrusion market. With the world's focus on resource conservation and circular economy principles, aluminum extrusions are poised to remain a cornerstone of modern manufacturing, providing versatile, sustainable, and high-performance solutions for generations to come.