Finepac Structures Is The Leading Trader, Exporter, And Service Provider Of Industrial Equipment

10th March 2019, India: Over the years, they have received remarkable trust and recognition from their clients. Their repeated purchases and engagement with the company has given them the courage to face their rivals and also has given them the urge to do better, by improvising the available services.

They are capable of carrying out various fabrication processes, by using their modern-sophisticated manufacturing facilities. Their services are for multiple industries, ranging from Structures, Random, Tower Packing, to Industrial Column Internals.

The company has working used oil refining processes to separate oil from the liquid. The re-refiners task is to eliminate all possible, contaminants and revive the oil to its initial state. The essential point to note is that the technology used by Finepac Structures is practically same to that employed to clean raw petroleum, the variation being that the level of pollution in used oil is much weaker than in unrefined oil.

Used oil refining decreased greenhouse gases and hence is a better way to handle the lube. It is easier on the atmosphere and modifies the oil into a renewable source. The field that deals with Oil-water separation are significant in several ways, as it has immediate-compelling indications for solving the problem of industrial oil wastewater and other oil/water pollution. The process is as such:

Dehydration eliminates unwanted elements from Water as is also useful for Oil-water separation: Water locates its way into several used oil storage spaces, so it’s the first piece that they are removing, by utilizing the process of evaporation. The water is gathered and handled in such a way that it causes no harm and then released.

The process of Light End Recovery: Lightweight substances are removed, along with water, the used oil passes onto the tall rescue towers where glycol and other light fuels are divided and stored.

The Fuel Stripping process: Heavier fuels are eliminated, for industrial application. The used oil is now treated, with radiation and vacuum processes which remove middleweight oils Structures have two types of Oil-water separators: 2-phase and 3-phase separators.

There are other solutions include Vacuum Distillation and Hydro Treating for removing impurities

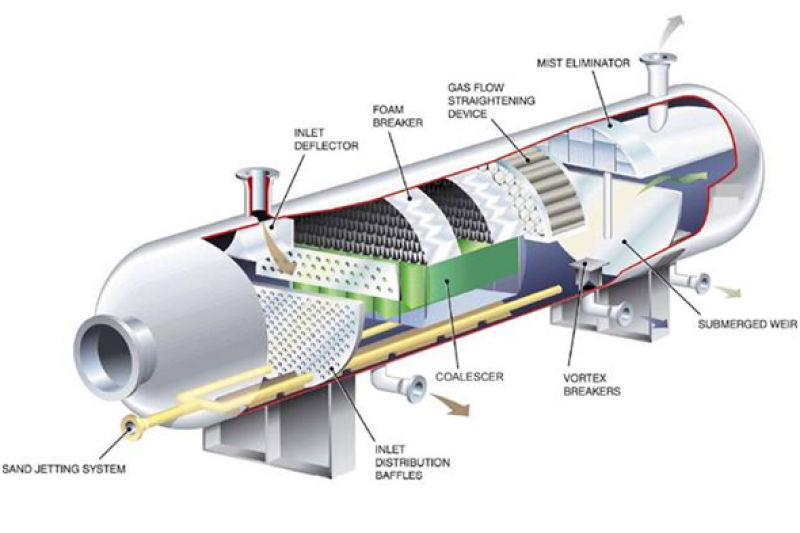

2 phase separators are devised especially to separate the oil from gas in a mixture. The water current entering the separator hits the inlet deflector which redirects the liquid and gas downstream to the liquid section where it starts separating. After a set interval, the water gets accumulated, in the bottom lifting a float to eliminate fluid.

3phase separators are used especially to deal with

The range of customized process tools used for mass transfer processes, distillation, solid-liquid separation, desorption, extraction, and many more are used, in the following industry sections as of now:

Organic chemicals,

Petrochemicals

Drug And Dye Intermediates,

Pharmaceuticals,

Agrochemicals,

Pesticides, And Fertilizers,

Oil And Gas Industries

Drugs.

About Finepac Structures

Finepac Structures deal in a broad variety of chemical process machinery that is considered for their useful functionality in mass transfer processes such as distillation, absorption, peeling, mixing, etc. Besides the dynamic team in Finepac Structures and modern machinery, the products manufactured here are highly energy durable, sturdy, corrosion free, and can endure outside forces, temperature, and pressure.