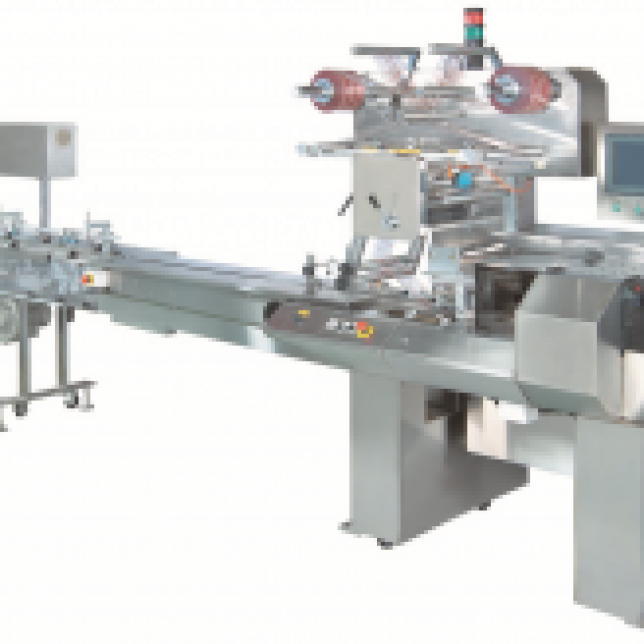

Machine Type

Automatic packaging system, reduce labor costs, productivity stable, continuing operations.

In-Line Feeder offers high speed and flexibility to the packaging line. Multiple belt conveyor system with automatic control of the speed of each belt enhances the capacity and efficiency. The speed of ILF is synchronized to the flow wrapper by the vacuum belt driven by the servo motor. The system is used for high speed in-line feeding of regular shaped product such as cookies ,chocolate bars. etc.

Features

- Durable, high productivity and low-noise by 4independent servo motors with electronic control enable 24hours nonstop high speed packaging.

- User-friendly human / machine interface control with 10.4inch colorful monitor and Dialogue type screen provides maximum operational convenience and is easy to learn.

- Comply with PIC/S-GMP specification and also equips USB port and automatic saving event log.

- 50 sets of recipe (bag length, temperature, speed, feeding position, film tension and cutting position) could reduce the initial lose providing high efficiency.

- High compatibility with different feeding systems: Desiccant dispenser, Card Magazine, Product Orientation Systems (for round product), Row distribution systems (for bar-shape product) and belt type feeding system…etc.

- Optional to (a) Auto Splicer (b) bar code reader (c) Rejection function.

Applicable Packaging Products

- Cake, chocolate, credit card, ice cream, biscuit, frozen food and similar, arriving in regimented rows form the processing production line.

Specification

| MODEL | HP-350VR + Auto Feeding system |

|---|---|

| Operating speed | 30 - 250 pack/min |

| Bag length | 70 - 180 mm |

| Max. film width (max. roll dia.) | 350 mm (300 mm) |

| Product width (max.) | 20 - 120 mm |

| Product height | Max. 50 mm |

| Main drive motor | 1 HP |

| Heater | 1600 W for center sealer, 1200 W for end sealer |

ApplicationPhoto GalleryMoviesFiles Download

-

Nutrition Bar and Chocolate Bar Packaging

Long style food packaging, such as nutrition bar and chocolate bar.Use with automatic alignment system can reduce labor costs and increase productivities.Can be installed water recycling system, ensure chocolate bar won't melt due to external factors.

-

Candy Packaging

Candy packaging. Can package both the square and circle shape candy. Auto feeding and aligning through the vibrator feeder and turntable. Turntable is customize, can make according to the candy's shape. Speed can up to 800 pack/min.

-

Cup Cake Packaging

A variety of cake packaging. Former baking section can combine with aligning conveyor and smart belt. Achieve automatically packaging, reduce labor pollution and increase productivity.

-

Ice Pop Packaging

For the ice pop packaging's sanitation and cleaning. Conveyor contact surface is made of stainless steel. Stainless steel is smoother and more difficult to cohere. It make the cleaning much easier and keep the packaging process's hygienic quality.Use with the automatic alignment feeding conveyor can reduce labor costs and increase productivity. If can combine with the production line, it can achieve fully automated production.