Factors Driving the Food Robotics Market

The report "Food Robotics Market by Type, Application (Palletizing, Packaging, Repackaging, Pick & Place, Processing), Payload (Low, Medium, Heavy), End-Use Industry, and Region - Trends & Forecast to 2022", The global food robotics market is estimated at USD 1.37 Billion in 2017 and is projected to reach USD 2.50 Billion by 2022, at a CAGR of 12.80% during the forecast period. The market is driven by factors such as higher demand for packaged foods, increase need to improve productivity, and increase in number of food safety regulations.

The articulated segment, by type, accounted for the largest market share in 2016.

The articulated robot by type had the largest market share in 2016. Articulated robots can range from simple two-joint robots to complex ten-joint robots. The more joints an articulated robot has, the greater its range of motion which makes it flexible for food processing. Moreover, articulated robots have a wide variety of payload capacities, which makes them useful in the food industry wherein there is a varied requirement for robots in the low to medium payload category.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=205881873

The medium segment, by payload, accounted for the largest market share in 2016.

The medium segment of the food robotics market by payload had the largest market share in 2016. The medium segment may be defined as robots with payload capacity ranging between 10 kg to 100 kg. In the food & beverage industry, the market for medium payload robots led in 2016, as most of the automated processes require a certain degree of flexibility to cater to the changing manufacturing needs, which is offered by robots in this category.

The Palletizing segment, by application, accounted for the largest market share in 2016.

The palletizing segment of the food robotics segment by application had the largest market share in 2016. This is due to reducing operating cost and labor requirements, increasing turnaround time and production, and reducing ergonomic issues; these properties help in increasing their demand in the food & beverage industry. Palletizing refers to the process of loading and unloading large and heavy boxes and parts to and from pallets in food & beverage manufacturing and distribution facilities and warehouses.

The beverage segment, by end-use industry, accounted for the largest market share in 2016.

The beverage subsegment of the food robotics segment by end-use industry had the largest market share in 2016. This is due to increased adoption of robots by beverage manufacturers to perform packaging, repackaging, and palletizing functions efficiently. They are used for packaging of beverages in polyethylene terephthalate (PET) & Clarified Polypropylene (PP) bottles, glass bottles, cans, and jars of various capacities, sizes, and shapes.

Speak to Analyst: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=205881873

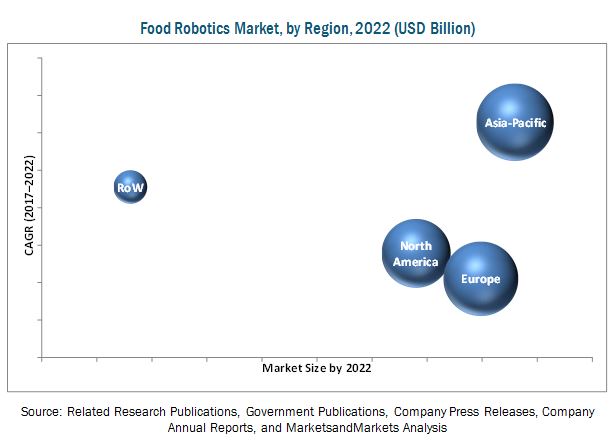

The Asia-Pacific region is projected to have the highest CAGR from 2017 to 2022

The Asia-Pacific region is projected to have the highest CAGR during the forecast period. The countries covered in the Asia-Pacific region is projected to be the fastest-growing market for food robotics due to the demand for ready-to-eat products has increased rapidly among consumers. The packaged food consumption growth increased due to urbanization in the Asia-Pacific region.

The key players in the food robotics market include:

- ABB Group (Switzerland)

- KUKA AG (Germany)

- Mitsubishi Electric Corporation (Japan)

- Kawasaki Heavy Industries Ltd. (Japan)

- Rockwell Automation, Incorporated (U.S.)

- FANUC Corporation (Japan)

- Seiko Epson Corporation (Japan)

- Yaskawa Electric Corporation (Japan)

- Staubli International AG (Switzerland)

- Mayekawa Mfg. Co. Ltd. (Japan)

- Universal Robots A/S (Denmark)

- Bastian Solutions Incorporated (U.S.)